Quality Control

We maintain strict quality control at every stage, ensuring each product meets international standards. Advanced testing and inspection guarantee reliability, safety, and consistent performance.

At KUNSHIDA, we implement a rigorous quality control system that spans the entire manufacturing process. From the selection of high-grade raw materials to precision machining and final assembly, every step is meticulously inspected. Each machine undergoes real-world performance simulation and multi-point testing to ensure stable operation, accurate packaging, and long service life. This commitment to quality allows us to deliver equipment that consistently meets international standards and earns long-term trust from global clients.

100%

24/7

100%

We control quality from the source by carefully selecting raw materials and critical components to lay a solid foundation for overall machine performance.

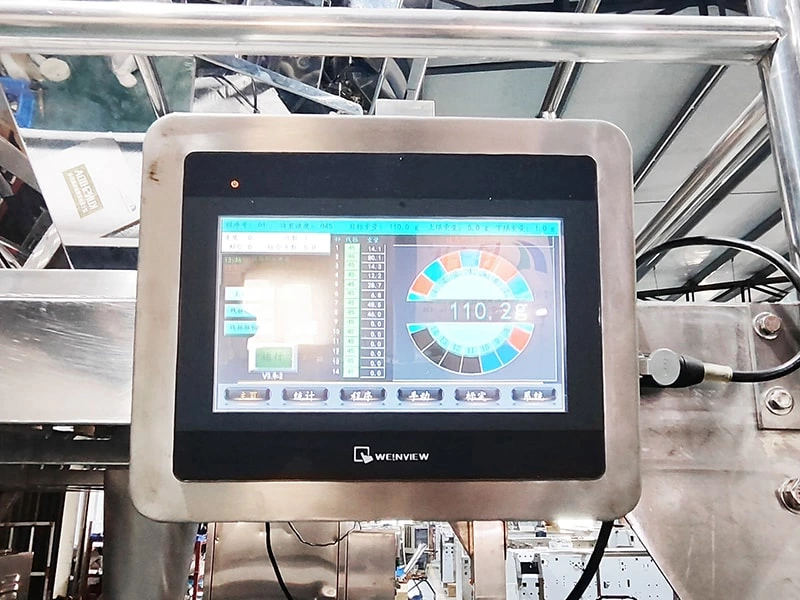

Every procedure follows standardized operating protocols, with digital monitoring systems ensuring precise and error-free assembly processes.

Each unit undergoes a complete series of functional and durability tests to guarantee stable operation and excellent customer experience.

Headquarters Address: No. 2, South Side Of Xilong Industrial Zone, Qishan Sub-district, Jinping District, Shantou City, Guangdong Province, China

Monday to Friday - 9:00 AM to 6:00 PM

Feel free to fill out our contact form below and our support team will get back to you within 24 hours.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details